Single Spindle Monitoring System Solution

Single Spindle Monitoring System Solution

Overview:

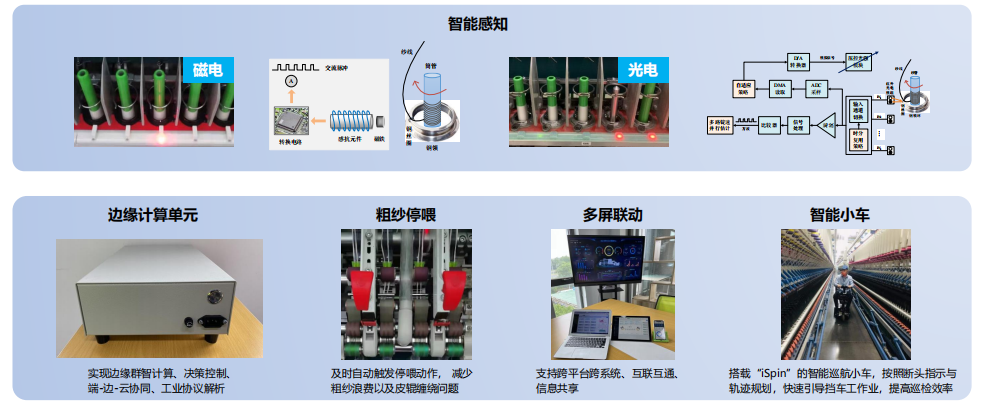

The system employs self-developed “magnetoelectric” and “photoelectric” sensors to monitor the motion status of spindles in real time. It identifies issues such as yarn breakage, empty spindles, weak twists, and defective spindles, providing combined light-based alerts for these conditions.

Based on the type and count of the spun material, the system automatically adapts the corresponding technical parameters, addressing the issue of high false alarm rates for yarn breakages caused by variations in spinning materials.

Advantages of the Single Spindle Monitoring System Solution:

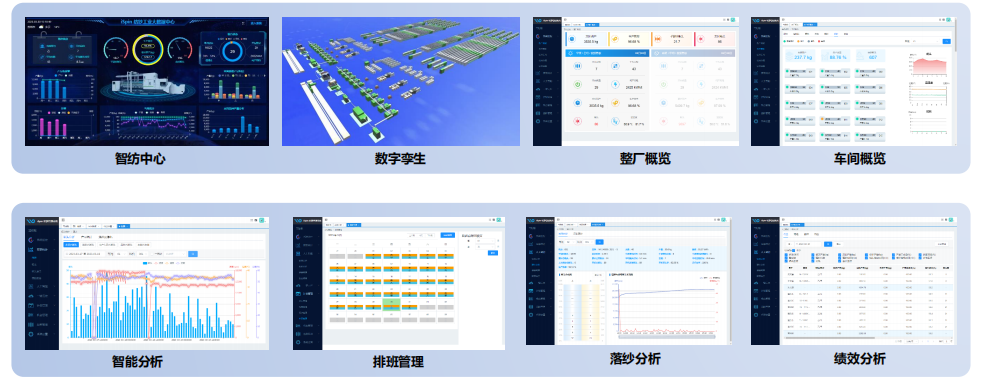

The solution deploys a unified big data platform across the entire process, breaking down “information silos.” By incorporating digital twin technology, it builds a 3D visualization platform for virtual-real interaction. This enables comprehensive monitoring of equipment status, processes, energy consumption, quality, and environmental data, as well as real-time situational awareness, data aggregation, and analysis.

OUR PROJECTS

An edge-cloud collaborative industrial internet platform for the spinning industry.

Customer Base:

Key customers include Wuxi First Cotton, Yagor Vietnam, Dezhou Fuhua, Qingdao Jifa, Anhui Huamao Group, Xinjiang Dongchunxing, Sichuan Heng Huiyuan, Suzhou Zhonghuang, Wugang Silver Dragon, Zibo Lutai, and more than 10 key customers in total. The platform has shipped over 880,000 spindles with contract values exceeding CNY 25 million.

Key Features:

Enables networking of industrial sensors, ensures interconnectivity, and provides online real-time monitoring.

Provides real-time monitoring and real-time alerts for combing, roving, coarse spinning, and fine spinning machines.

Offers professional and user-friendly data mining and statistical analysis tools.

Provides comprehensive reports on weaving production data mining and statistical analysis that are both professional and easy to use. These reports help customers identify problems at no extra cost, providing clear insights into planning scheduling, process quality, and production operations for effective management.

Promotes the shift from traditional to modern practices in the spinning industry, enabling full lean production.

Maximizes equipment utilization, improves equipment utilization rates, achieves intelligent scheduling, and enhances production efficiency.