RFID Electronic Shelf Solution

RFID Electronic Shelf Solution

Overview:

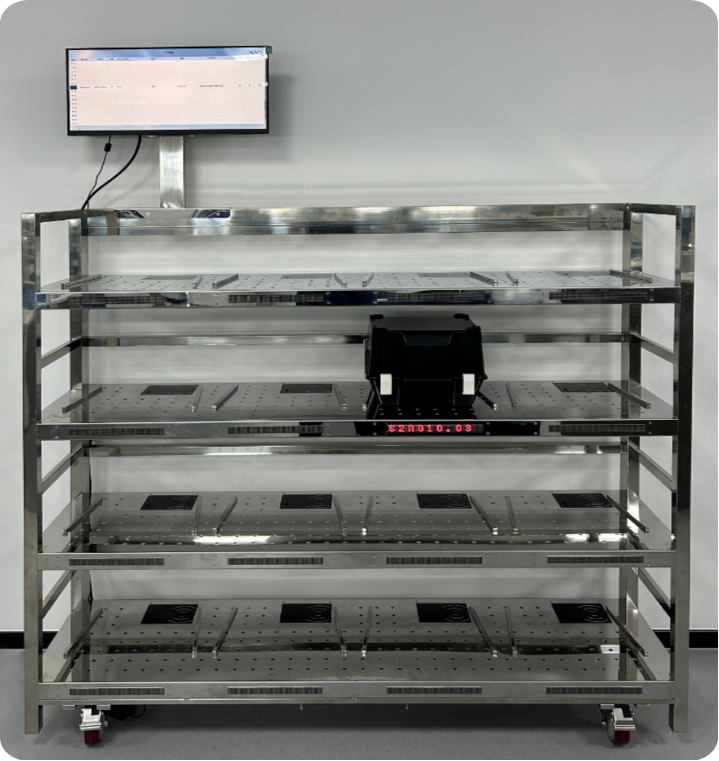

The RFID Electronic Shelf System integrates sensors, IoT, and cloud computing technologies to enable real-time monitoring of goods during storage. It provides functions such as goods identification and positioning, information display, backend management, and tracking traceability.

The system offers open third-party interfaces, supporting seamless integration and data interoperability with AMHS, intelligent stackers, AGVs (Automated Guided Vehicles), MES, and other systems and equipment. This facilitates intelligent management of goods during storage and transportation.

Features of the RFID Electronic Shelf Solution:

Goods Identification: Accurately and efficiently reads RFID tags attached to goods using RFID readers.

Goods Access Detection: Monitors the placement and retrieval of items on shelves using infrared detection.

Goods Positioning: Precisely locates the storage position of goods, down to the specific shelf layer or slot.

Shelf Information Display: Optional screens can be equipped to display goods information, access records, and more.

Access Notification: Features LED strips or indicator lights that work in conjunction with the management platform to provide visual cues during goods placement or retrieval.

Communication Methods: Shelves support communication with the management platform via wired networks or wireless Wi-Fi.

Management Platform: A comprehensive management platform ensures unmanned and intelligent goods management, offering features such as inventory counting, remote search, access record queries, and goods inbound/outbound management.

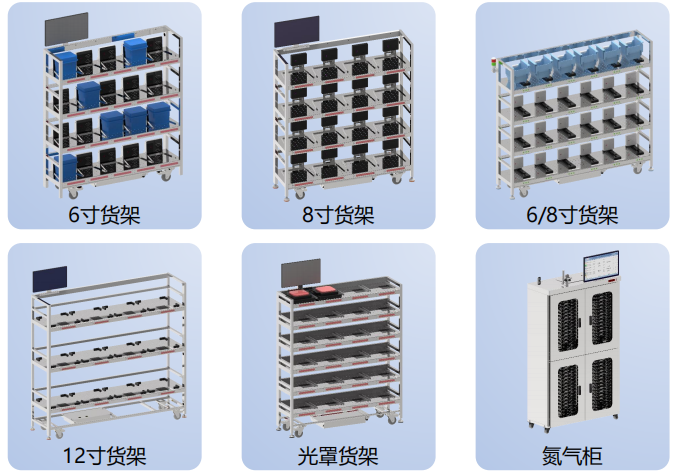

Customizable Product Forms

The RFID Electronic Shelf Solution can be tailored to meet specific requirements, ensuring flexibility and adaptability for various application scenarios.

OUR PROJECTS

Electronic Shelf Material System

The Electronic Shelf Material System has been successfully implemented in over 10 semiconductor manufacturing companies, including Zhonghuan Advanced, Zhaoxin Semiconductor, Zhanxin Electronics, and NAURA Technology Group Co., Ltd.

Application Scope:

Offers 10+ different configurations, covering 6-inch, 8-inch, and 12-inch wafers, as well as nitrogen cabinets, read/write stations, wafer cassettes, wafer transfer boxes, reticle boxes, and probe card boxes.

Key Features and Benefits:

Hand Ring Scanning: Records the responsible personnel for material storage and retrieval, enhancing accountability.

MES Integration: Supports remote material location queries and maintenance reminders via the Manufacturing Execution System (MES).

Read/Write Station Management: Links with the platform for automated batch management.

Multi-Level Alerts: Provides warnings for read failures, incorrect material retrieval, and un-scanned items, ensuring operational accuracy.

Advanced Integration: Seamlessly connects with customer MES systems, PDA scanning, and cleaning operations, offering a range of specialized functionalities.

This system has proven its versatility and efficiency across the semiconductor industry, meeting diverse material management needs with cutting-edge technology.