Intelligent Pipeline System

Intelligent Pipeline System

Introduction:

Banline Intelligent Pipeline System leverages sensors, data platforms, AI technologies, and other advanced tools to create an integrated platform for real-time monitoring and early warning of pipeline operations, optimized inspections, and full lifecycle traceability of assets. By implementing the following features, it significantly enhances pipeline asset management efficiency, reduces leakage rates, and lowers labor costs, with comprehensive costs being less than one percent of traditional methods.

Solution Introduction:

Through sensors, data platform, AI technology and other means, the AI pipe network realizes an integrated platform of real-time monitoring and early warning of pipe network operation status, inspection optimization, pipe network risk prediction and full life cycle traceability of assets. Through the realization of the following functions, the efficiency of pipe network asset management is effectively improved, the leakage rate is reduced, the labor cost input is reduced, and the comprehensive cost is much lower than the traditional method.

Advanced Core Technology:

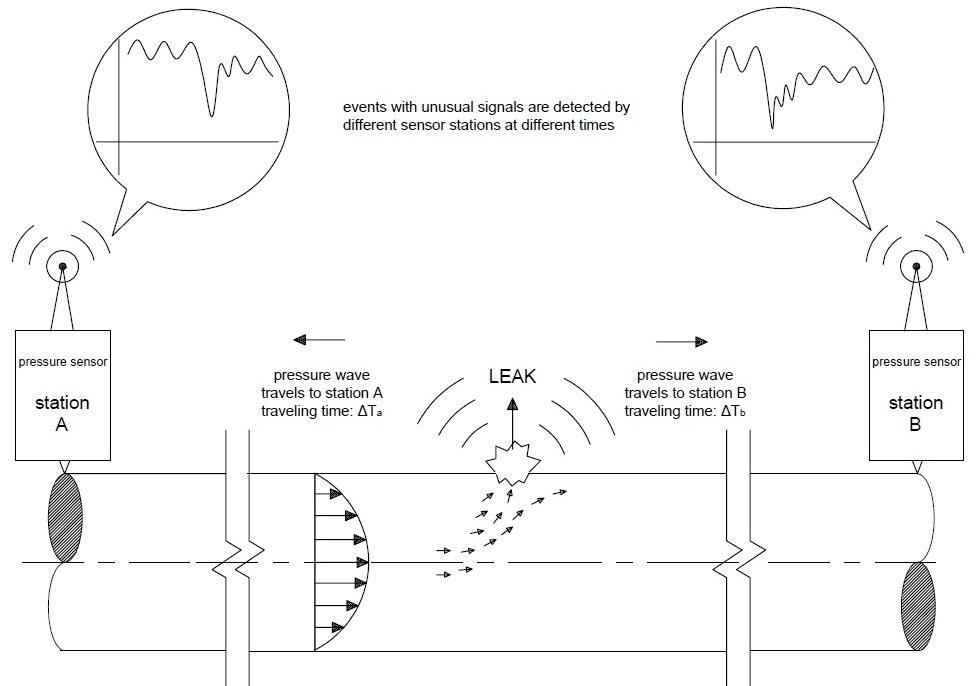

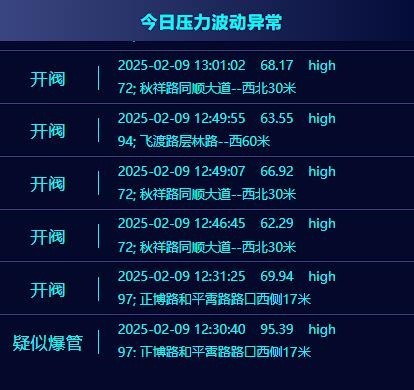

High-Frequency Transient Pressure Wave Sensing Technology Through high-frequency detection at 100 times per second, the system captures and analyzes transient pressure fluctuation signals in pipelines caused by events such as leaks or bursts. This enables all-weather, precise, and efficient pipeline monitoring and accurate localization of abnormal events.

Low-Cost Leakage Detection:

Compared to traditional leakage monitoring methods, the system collects high-frequency pressure data and integrates high-frequency transient pressure wave sensing technology with advanced algorithms such as artificial intelligence. The comprehensive cost is less than one percent of traditional methods. Additionally, the use of sensors and IoT technology enables 24/7 monitoring, reducing the frequency and cost of manual inspections.

Extensive Coverage:

A single data station can cover one to two square kilometers of pipelines, enabling low-density, high-frequency real-time monitoring. This significantly reduces the number of sensors required and associated maintenance costs while improving the coverage and efficiency of pipeline monitoring.

Enhanced Safety and Reduced Incidents:

24/7 Monitoring to Minimize Safety Risks: Real-time alerts for leaks and pressure anomalies reduce the risk of pipe bursts and leakage incidents.

Construction Safety Management:

Digitized storage of construction acceptance data ensures compliance and minimizes future safety hazards.

Installation Model of the Intelligent Pipeline System:

Banline Intelligent Pipeline System adopts the world-leading high-frequency transient pressure wave sensing technology. By collecting high-frequency pressure wave data from pipelines and combining it with cutting-edge algorithms like machine learning and artificial intelligence, the system enables monitoring and precise localization of pipeline leaks and faults.

The Intelligent Pipeline System operates autonomously using solar power, making it suitable for various complex long-distance pipeline scenarios. Additionally, RFID equipment installation allows for full lifecycle management of the pipeline network. When solar panels absorb sunlight, light energy is converted into electrical energy. Part of this energy powers the system’s real-time operations, while the surplus is stored in batteries to ensure continuous power supply during nighttime or rainy weather.

OUR PROJECTS

Artificial Intelligence Monitoring

System for Coal Mine Water Pipeline

Project Overview:

This project showcases an advanced AI-based monitoring system for a coal mine water pipeline, ensuring safety and operational efficiency in a demanding environment.

Key Features and Benefits:

24/7 Uninterrupted Monitoring: Ensures coal mine safety through continuous real-time monitoring.

Stable Data Transmission in Harsh Environments: Guarantees reliable data communication under challenging conditions.

Online Monitoring of Pipeline Cathodic Protection: Provides real-time insights into corrosion prevention measures.

Remote Intelligent Valve Control: Enables remote valve shutdown, flow rate, and pressure regulation for enhanced control.

Proactive Issue Detection: Identifies potential problems early, reducing the need for manual inspections and minimizing costly repairs due to unexpected incidents.

Compliance with National Policies: Aligns with China’s policies on coal mine safety production and the development of smart mining initiatives.

This successful implementation demonstrates the power of AI-driven monitoring in enhancing safety, efficiency, and compliance in coal mine operations.

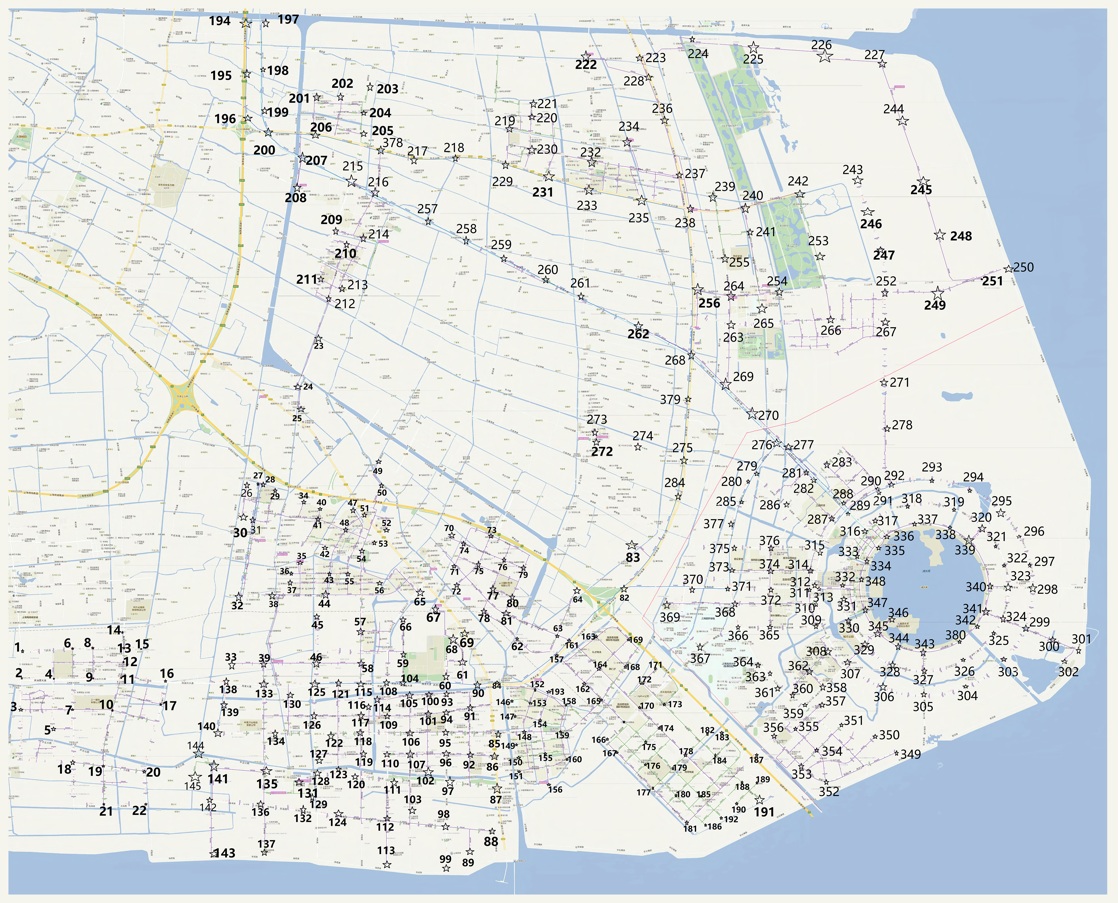

Lingang Water Supply Smart Pipeline Network

355 Data Sites

315 Square Kilometers

1,400 Kilometers of Water Supply Pipelines

This project represents the largest-scale smart management system for urban water supply networks in China, showcasing advanced technology in a challenging urban environment.

Key Features and Benefits:

Suitable for Long-Distance and Complex Environments: Designed to monitor pipelines effectively in extended and intricate settings.

Supports Intelligent Operations and Maintenance: Enhances pipeline longevity through smart maintenance strategies.

Improves Construction Management Efficiency: Reduces labor costs by streamlining processes.

Ensures Project Safety: Boosts reliability and minimizes risks throughout the project lifecycle.

This successful deployment in Shanghai Lingang demonstrates the transformative potential of smart pipeline technology in urban water management.