Undersea Piping

TCP-Ultra™ Thermoplastic Composite Pipe (TCP/RTP)

TCP-Ultra™ Thermoplastic Composite Pipe (TCP/RTP)

for Petroleum and Natural Gas Applications

Product Introduction:

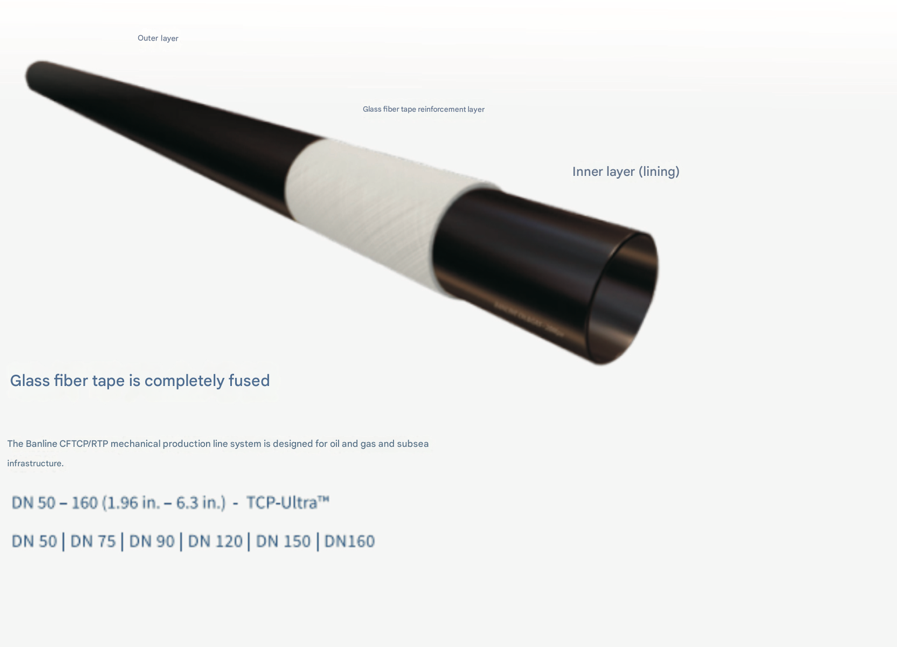

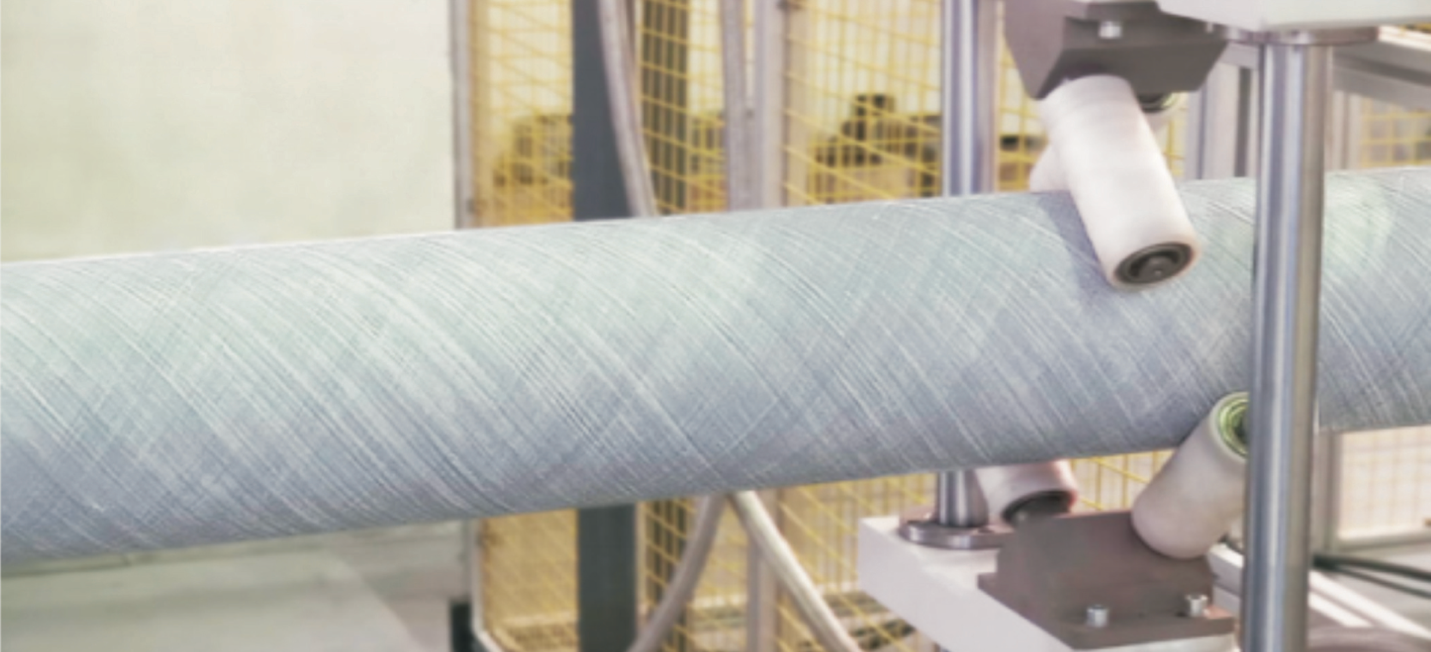

A fusion-welded continuous glass fiber reinforced thermoplastic composite pipe production system.

Product Features:

- High Pressure Tolerance: Maximum pressure resistance reaches 60 MPa, which is over 40 times that of standard plastic pipes.

- High Temperature Resistance: Maximum operating temperature reaches 90°C. The inner layer uses PERT-1 or PERT-2, exceeding the temperature resistance of typical plastic pipes by more than 60°C.

- Extended Service Life: Certified 50+ years of service lifespan is 6 times longer than metal pipes and twice as long as standard plastic pipes, resulting in comparable cost savings of up to 70%.

- Corrosion Resistance: Corrosion-free and environmentally friendly, ensuring long-term reliability even in chemically harsh environments.

- Thinner Wall Thickness: As the inner liner and outer sheath generally do not contribute to mechanical strength, with a glass fiber-reinforced inner layer and outer layer the pipe wall is only one-quarter the thickness of traditional plastic pipes, resulting in a 30% increase in flow capacity.

- Lighter Weight: 40% lighter than standard plastic pipes, and 30% lighter than steel wire-reinforced composite pipes, reducing transport and installation costs.

- Customizable Maximum Pressure and Layer Count: The number of reinforcement layers can be flexibly designed based on specific pressure requirements and winding configurations.

- Multiple Material Options:

- PE100+ for Inner and Outer Layers

- PERT as the Inner Layer and PE100+ as the Outer Layer

- Multi-layer co-extrusion core pipe is also applicable.