Fiber-Reinforced Polyethylene Liquid Pipe for Mining Use

Product Features:

It has the advantages of high-pressure resistance, corrosion resistance, good chemical stability, aging resistance, long service life, low fluid resistance, low overall cost, convenient transport and installation, time and cost savings, anti-static, flame-retardant, and high mechanical strength.

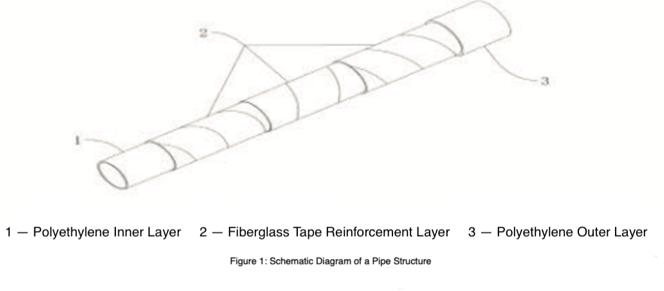

Product Structure:

Using fiberglass tape as the intermediate reinforcement layer, with the inner and outer layers made of modified polyethylene resin, the inner and outer layers are fused with the reinforcement layer into one body. Through an extrusion molding process, the materials are compounded into a new type of anti-static, flame-retardant composite material pipe. The structural schematic is shown in Figure 1.

Product Standards:

The standards followed for our company’s production of RTP continuous fiberglass tape-reinforced pipes for coal mines are:

- C/T 189-2007 Steel wire mesh framework plastic (polyethylene) composite pipes and fittings

- MT/T SS8.1—2005 Plastic pipes for coal mine underground use – Part 1: Polyethylene pipes

- Q/XLS004-2023 RTP continuous fiberglass tape sintered reinforced pipes for coal mine use

Pipe Connection Methods and Installation Requirements:

- Pipe Connection Method

Flange connection: When the pipe leaves the factory, crimp-type metal fittings are installed on both ends using a pipe locking machine. The user only needs to connect the flanges to the existing equipment or pipeline. Place the rubber gasket concentrically with the flange, then evenly tighten the bolts. - Pipe Installation Requirements

Pipe installation should meet the following requirements:

(1) Before construction and installation, specifications such as pipe type, fittings model, and working pressure should be verified. Pipes of different purposes, wall thicknesses, and pressure ratings cannot be connected together. Use only after confirmation. Pipe markings should face outward in a clearly visible position.

(2) During installation, there must be no axial twisting. Elbows should be used at bends; do not force straight pipes to correct alignment.

(3) For buried installations in pipe trenches, the pipeline must be pre-fixed (e.g., using piers, brackets, hangers) to ensure that under pressure or water hammer, the pipe will not move significantly. Because polyethylene pipes have lower stiffness than steel pipes, fixation must also prevent the pipe from swinging or buckling under pressure. Generally, for straight horizontal installations, the distance between two fixed points should not exceed 2 meters. For horizontal installations, the distance between two fixed points should not exceed 10 times the pipe diameter.

(4) Pipe fittings in the pipeline, such as couplings, tees, and reducers, are points where fluid undergoes significant changes, which can cause turbulence and vibration. These points also bear axial forces caused by fluid pressure. Therefore, supports, brackets, or piers must be used to secure them.

(5) When using supports, brackets, or hangers for fixation, U-shaped clamps or other types of pipe clamps should be installed on the pipe or fitting. Since the surface of polyethylene pipes is smooth, rubber pads must be placed between the pipe surface and the clamp to prevent slippage. Then, tighten the pipe clamp with screws to prevent movement. Pipe clamps should be firmly connected to piers, supports, or brackets via bolts.

For valves, the valve body must be fixed. Steel parts must be connected to the valve, fixed in place, and then connected to the pipeline with fittings.

(6) The biggest hidden danger in pipelines is leakage. Therefore, valves must be installed in the piping system for daily maintenance and emergency shutdown, but valve placement should not be too dense.

(7) At the end of each installation shift, pipe openings should be temporarily sealed to prevent debris from entering. After installation is completed, a quality inspection must be performed. If requirements are not met, rework is necessary.

Pipe Specifications:

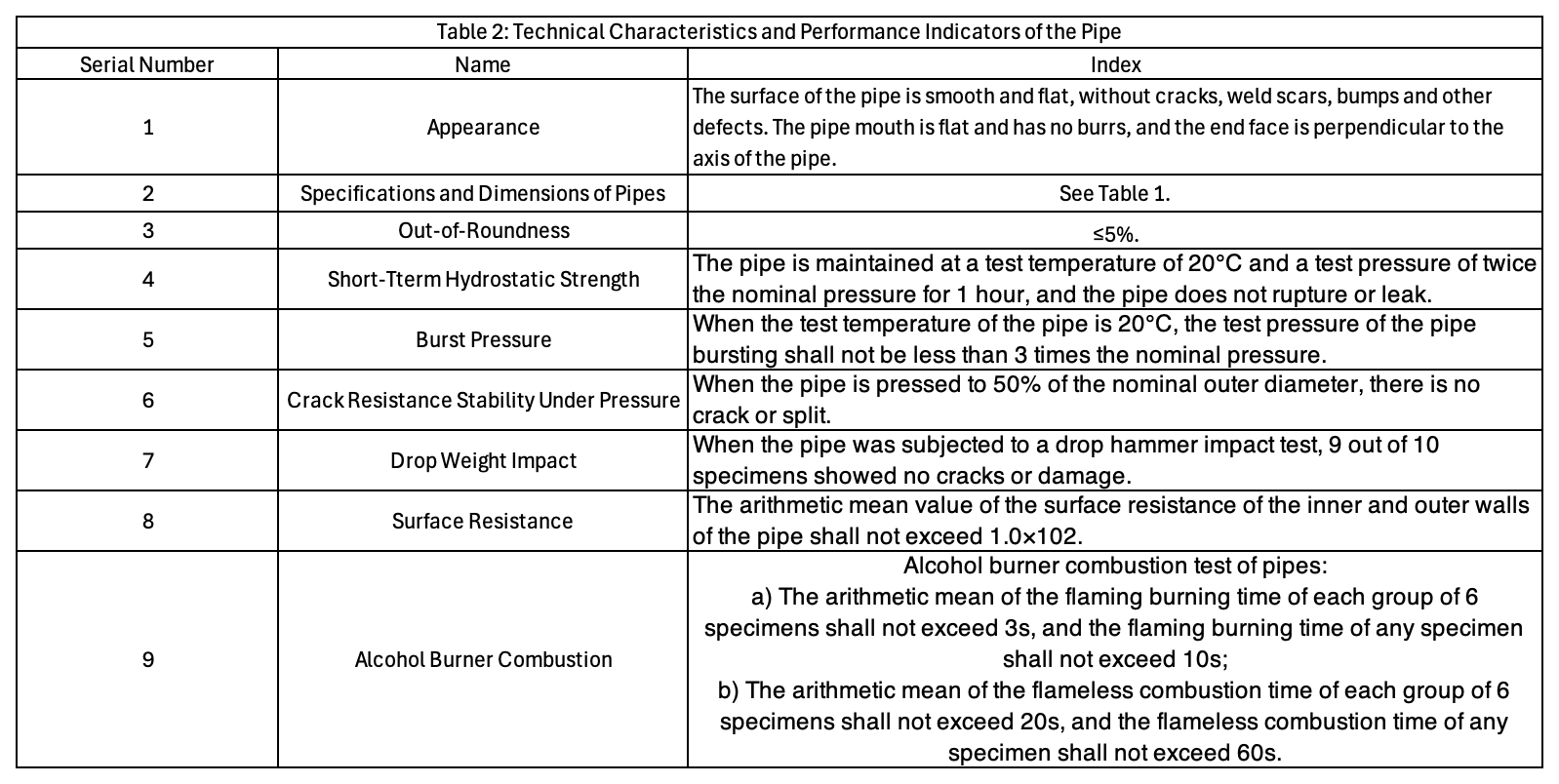

The nominal pressure, nominal outside diameter, wall thickness and its tolerance, reinforcement layer material, and the number of winding layers of the pipe shall comply with the requirements specified in Table 1.

Product Technical Characteristics:

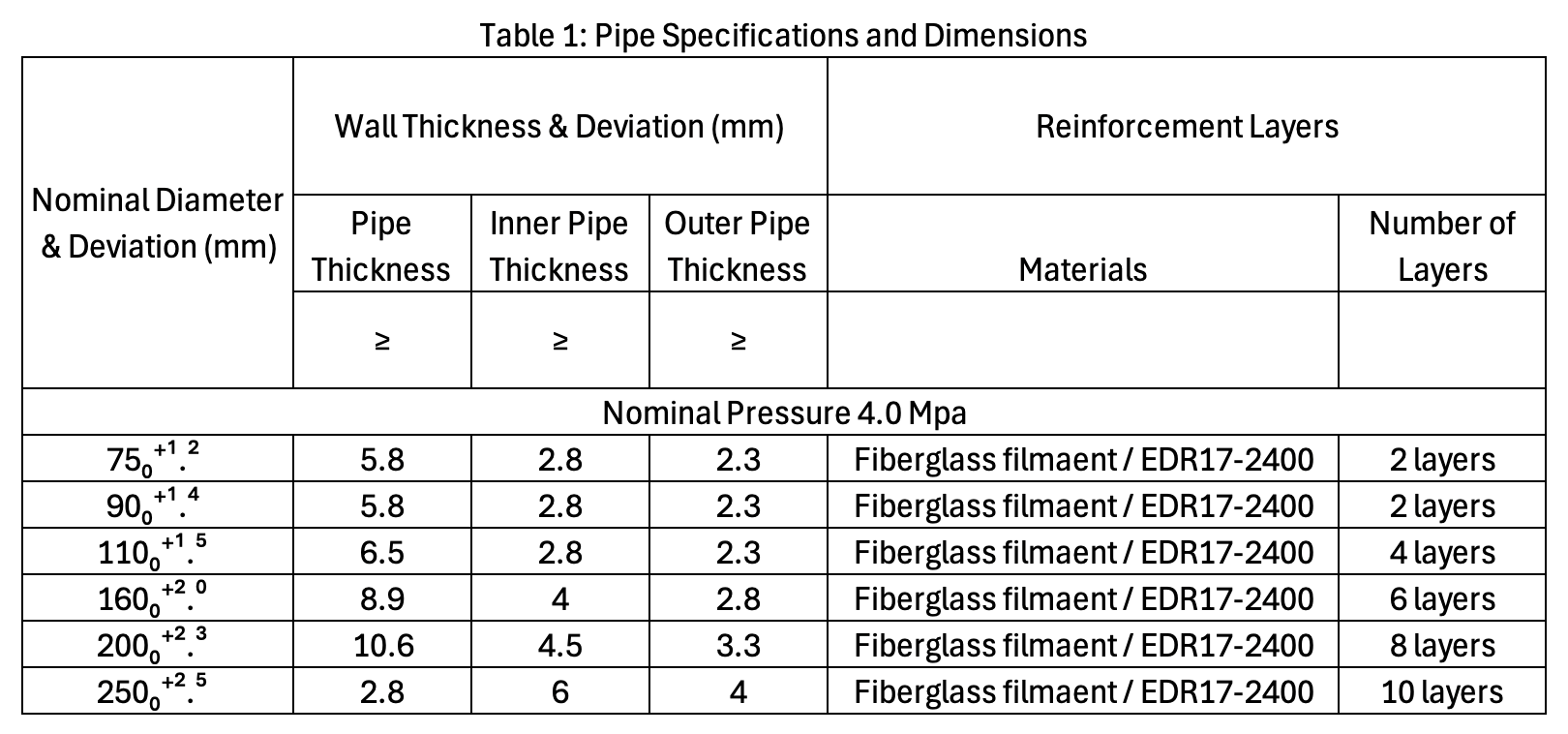

The technical characteristics and performance indicators of the pipes produced by our company are shown in Table 2.