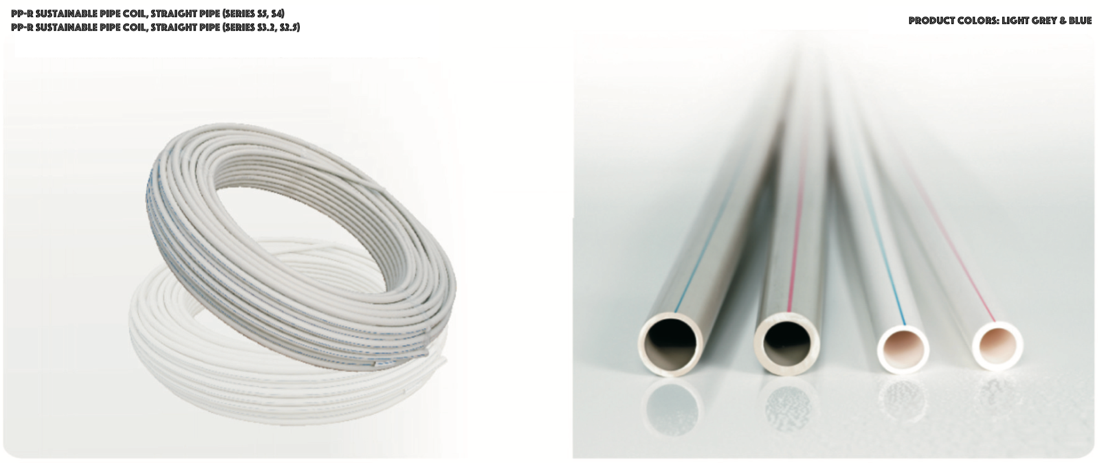

PP-R Water Supply Pipe

Product Introduction:

Our PP-R piping products are manufactured in strict compliance with the ISO 9001 quality management system, meeting all requirements of GB/T 18742.2, GB/T 18742.3, and GB/T 17219 hygiene standards, as well as relevant health and safety evaluation regulations set by the National Health Department.

As the preferred choice for potable water systems in developed countries worldwide, PP-R drinking water pipes utilize homogeneous fusion welding technology for both hot and cold-water distribution. These pipes significantly outperform comparable products in both technical performance and economic indicators, particularly in their exceptional hygienic properties that meet stringent health and environmental standards throughout the entire product lifecycle – from production and use to disposal and recycling.

Product Features:

- Hygienic & non-toxic – Made of polyolefin (only carbon/hydrogen elements) for guaranteed drinking water safety.

- Easy installation – Features homogeneous thermal fusion for fast, leak-proof connections.

- Energy efficient – Low thermal conductivity (0.24W/m·K) reduces heat loss by 99% vs metal pipes.

- Lightweight yet strong – Weighs 1/8 of steel pipes with superior pressure resistance.

- Smooth interior – Minimizes flow resistance to lower pumping costs.

- Heat resistant – Withstands 70°C continuous/95°C short-term water temperatures.

- Corrosion-proof – Prevents scaling and eliminates rust contamination.

- Long-lasting – 50+ year service life outperforms conventional piping.

Product Applications:

- Cold and hot water pipeline systems.

- Heating systems, including floor, wall panel heating, and radiant heating systems.

- Pure water pipeline systems.

- Central (centralized) air conditioning systems.

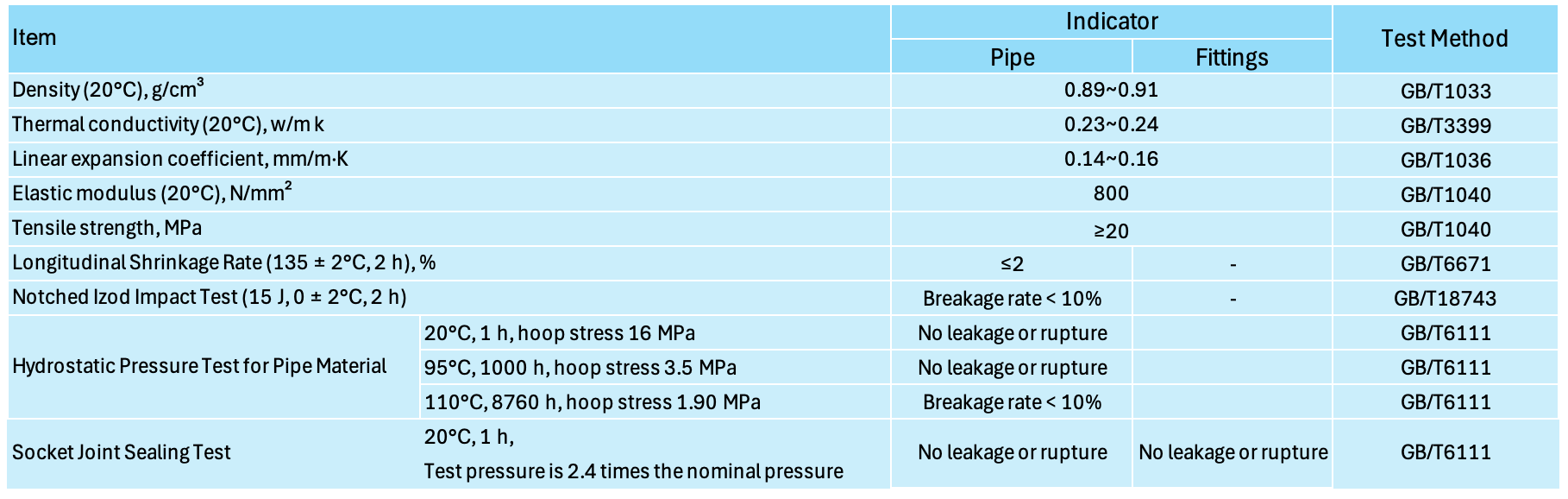

Product Specifications:

Pipe material specifications are represented using d × e, where d is the nominal outer diameter and e is the wall thickness. Their nominal values and allowable deviations are shown in the table below.

Product Performance Indicators:

Pipe Connectors:

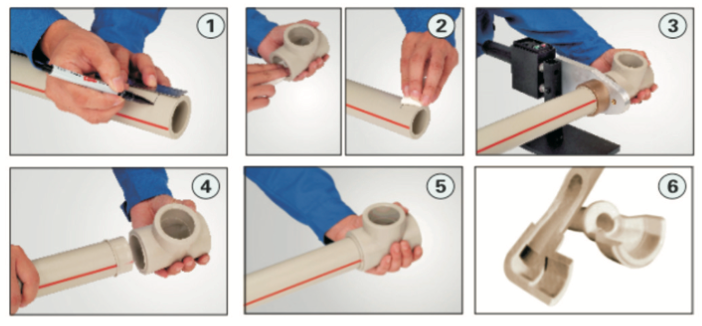

- Marking– After pipe preparation, mark the insertion depth on the pipe end.

- Cleaning– Clean the connecting surfaces of both the pipe and fitting. Insert the pipe into the socket of the fitting.

- Heating– Use a heat fusion machine to heat the pipe and fitting. Ensure heating parameters comply with the machine’s technical requirements.

- Fusion– Once heated, immediately remove both parts and insert the pipe straight into the fitting (without rotation) up to the marked depth, forming a uniform bead around the joint.

- Protection– After welding, cover the joint with a protective sleeve.

- Result– The pipe and fitting fuse into a seamless, monolithic unit, achieving a flawless bond.

Water Supply Pipe Materials:

Pipe Fittings & Tools: