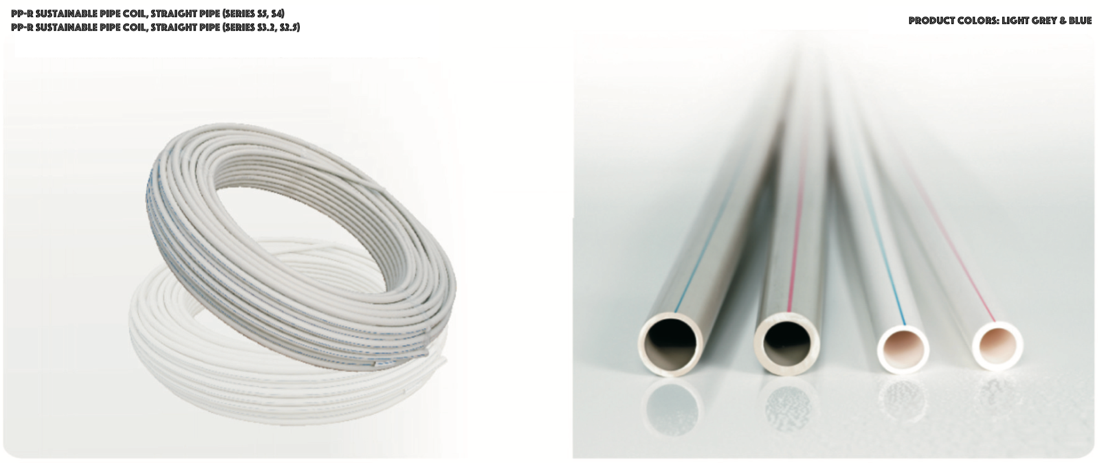

PPR Water Supply Pipe

Product Introduction

Our PP-R piping products are manufactured in strict compliance with the ISO 9001 quality management system, meeting all requirements of GB/T 18742.2, GB/T 18742.3, and GB/T 17219 hygiene standards, as well as relevant health and safety evaluation regulations set by the National Health Department.

As the preferred choice for potable water systems in developed countries worldwide, PP-R drinking water pipes utilize homogeneous fusion welding technology for both hot and cold-water distribution. These pipes significantly outperform comparable products in both technical performance and economic indicators, particularly in their exceptional hygienic properties that meet stringent health and environmental standards throughout the entire product lifecycle – from production and use to disposal and recycling.

Product Features

- Hygienic & non-toxic– Made of polyolefin (only carbon/hydrogen elements) for guaranteed drinking water safety.

- Easy installation– Features homogeneous thermal fusion for fast, leak-proof connections.

- Energy efficient– Low thermal conductivity (0.24W/m·K) reduces heat loss by 99% vs metal pipes.

- Lightweight yet strong– Weighs 1/8 of steel pipes with superior pressure resistance.

- Smooth interior– Minimizes flow resistance to lower pumping costs.

- Heat resistant– Withstands 70°C continuous/95°C short-term water temperatures.

- Corrosion-proof– Prevents scaling and eliminates rust contamination.

- Long-lasting– 50+ year service life outperforms conventional piping.

Product Applications

- Hygienic & non-toxic– Made of polyolefin (only carbon/hydrogen elements) for guaranteed drinking water safety.

- Easy installation– Features homogeneous thermal fusion for fast, leak-proof connections.

- Energy efficient– Low thermal conductivity (0.24W/m·K) reduces heat loss by 99% vs metal pipes.

- Lightweight yet strong– Weighs 1/8 of steel pipes with superior pressure resistance.

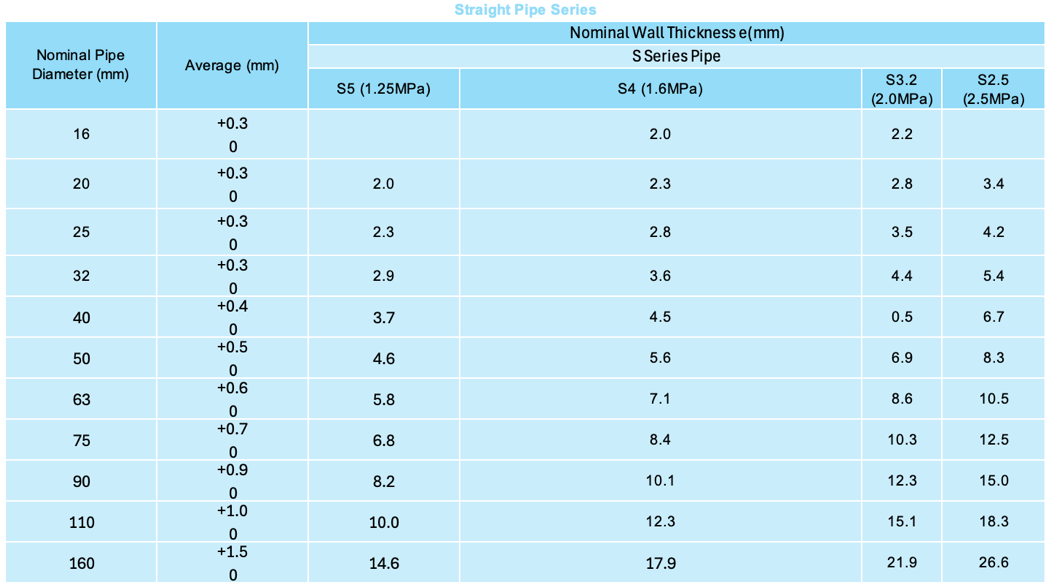

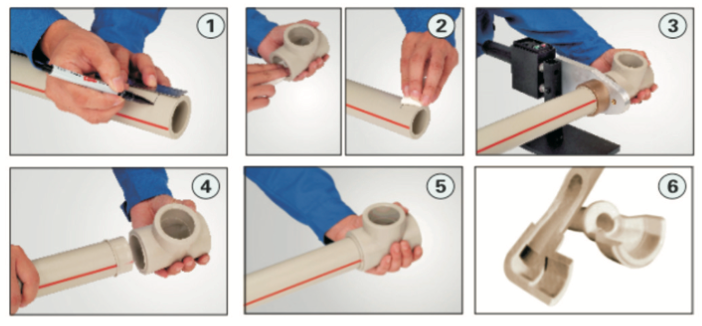

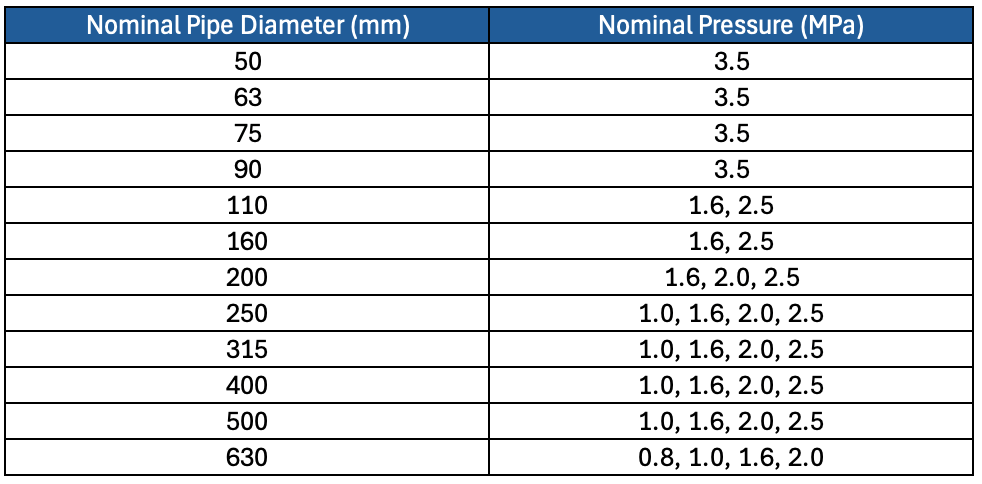

Product Specifications

Pipe material specifications are represented using d × e, where d is the nominal outer diameter and e is the wall thickness. Their nominal values and allowable deviations are shown in the table below.

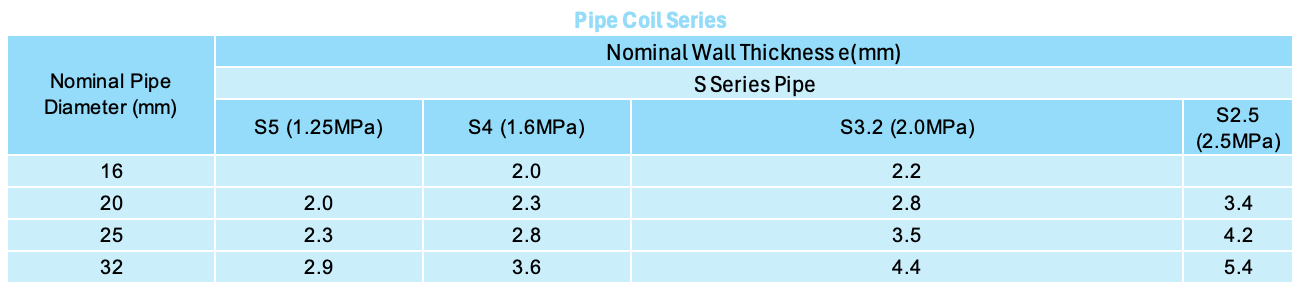

Product Performance Indicators

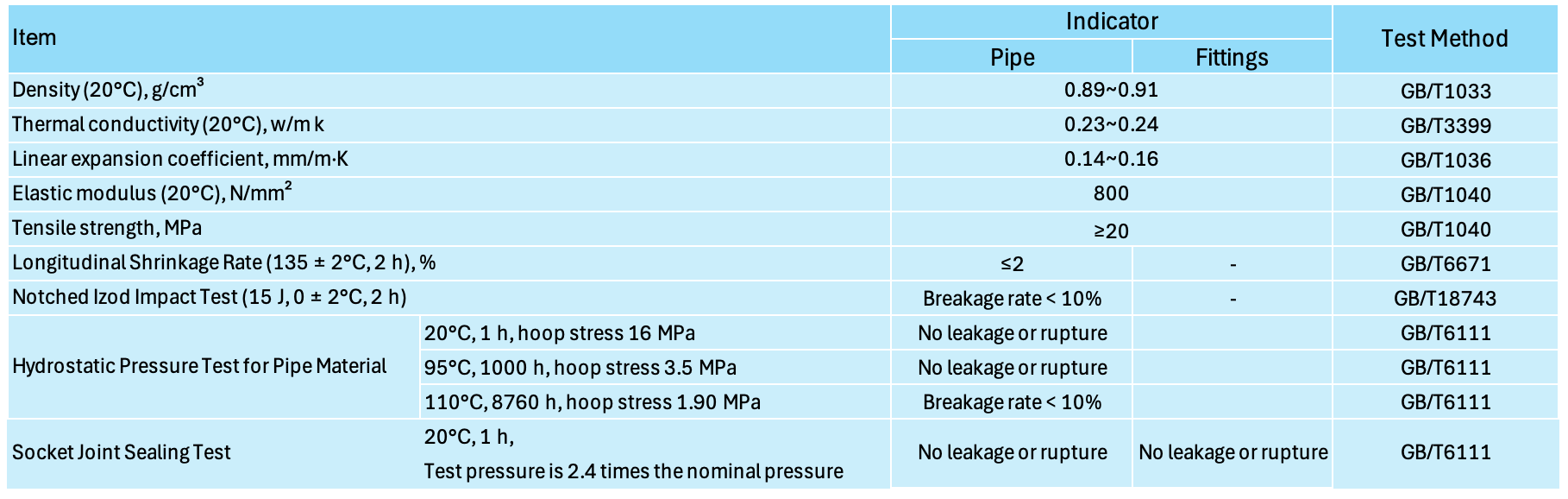

Pipe Connectors

- Marking– After pipe preparation, mark the insertion depth on the pipe end.

- Cleaning– Clean the connecting surfaces of both the pipe and fitting. Insert the pipe into the socket of the fitting.

- Heating– Use a heat fusion machine to heat the pipe and fitting. Ensure heating parameters comply with the machine’s technical requirements.

- Fusion– Once heated, immediately remove both parts and insert the pipe straight into the fitting (without rotation) up to the marked depth, forming a uniform bead around the joint.

- Protection– After welding, cover the joint with a protective sleeve.

- Result– The pipe and fitting fuse into a seamless, monolithic unit, achieving a flawless bond.

Water Supply Pipe Materials

Pipe Fittings & Tools

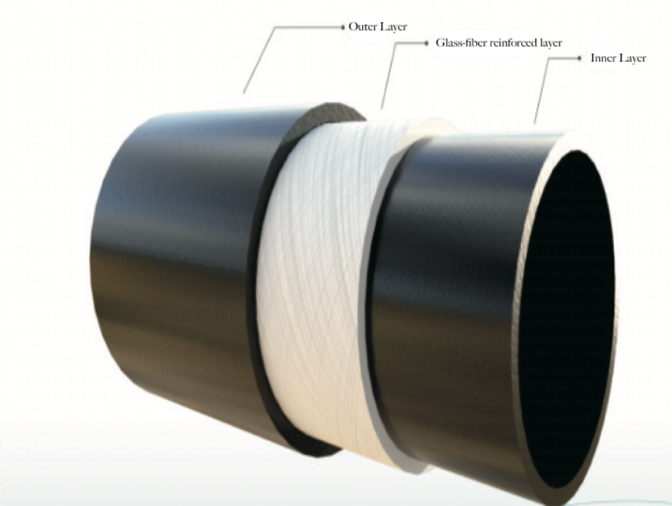

Continuous Glass Fiber-Reinforced Polyethylene Composite Pipe

Product Introduction

This is a new type of structural wall pipe that uses polyethylene resin as the inner and outer layers, with pre-impregnated glass fiber composite tape continuously wound and sintered as the reinforcement layer, fusing the three layers into a single integrated structure.

Compared to pipes of the same specifications, continuous glass fiber-reinforced polyethylene composite pipes not only significantly enhance their working pressure and expand their application range but also improve their high-temperature resistance and corrosion resistance. Additionally, they feature thinner wall thickness, lighter weight, and offer a higher cost advantage.

Product Features

Product Specifications

Product Parameters

Pipe Fitting Series

PE Water Supply Pipe

Product Introduction

PE water supply pipe is a type of piping made from polyethylene (abbreviated as PE) as the raw material. Due to its excellent physical and chemical properties, it is widely used in water supply projects, particularly in municipal water supply, agricultural irrigation, and industrial drainage systems.

Product Features

The primary material of PE water supply pipes is polyethylene, which offers high strength, heat resistance, corrosion resistance, non-toxicity, and wear resistance. These characteristics make PE pipes an ideal replacement for traditional metal pipes (such as iron pipes), especially in applications requiring corrosion resistance and long-term durability.

Product Applications

- Municipal Underground Water Supply– PE water pipes are suitable for urban water supply networks, providing clean and stable water sources.

- Building Water Supply & Drainage– In the construction industry, PE pipes are used for indoor and outdoor water supply and drainage systems.

- Agricultural Irrigation– PE pipes are used in drip irrigation, sprinkler systems, and drainage, improving water resource efficiency.

- Industrial Use– PE pipes are widely applied in industrial water transportation, drainage, and sewage systems.

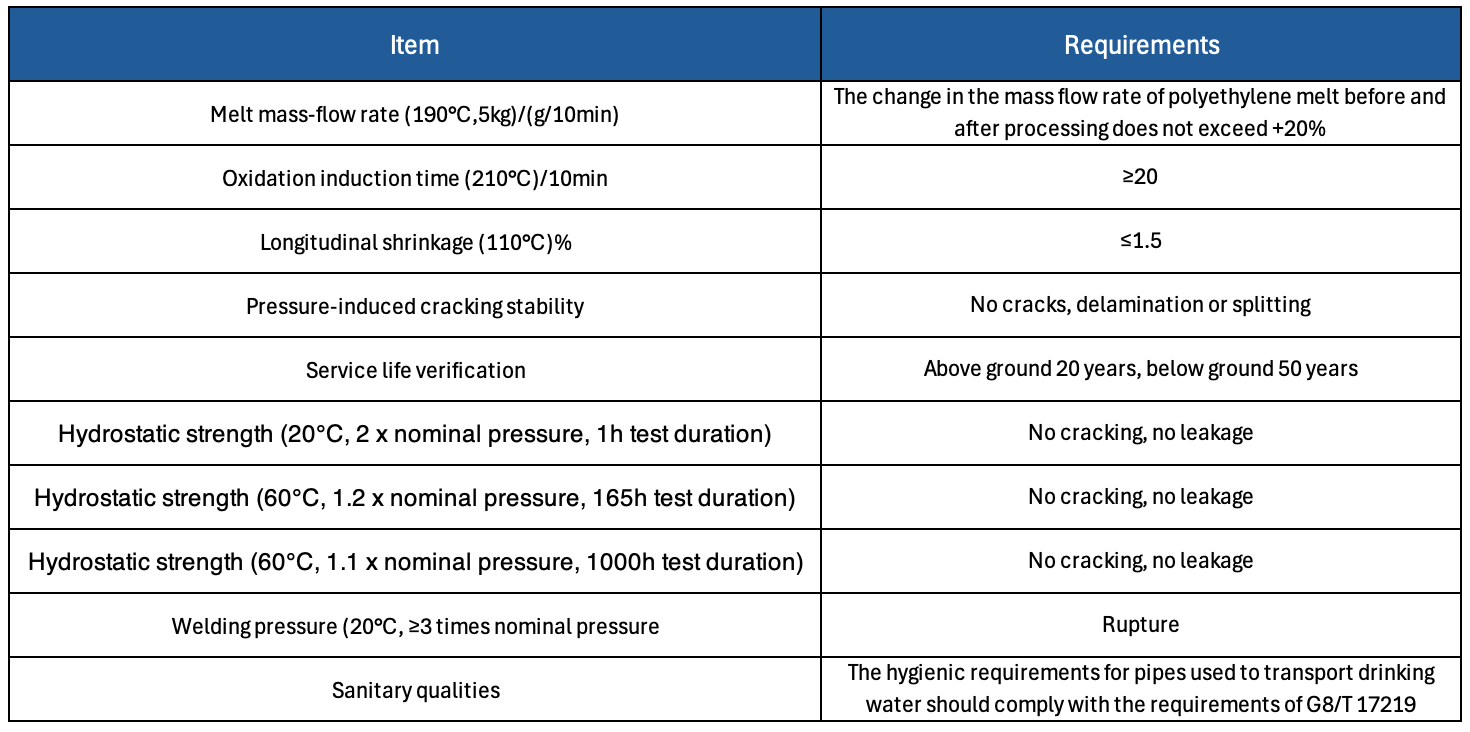

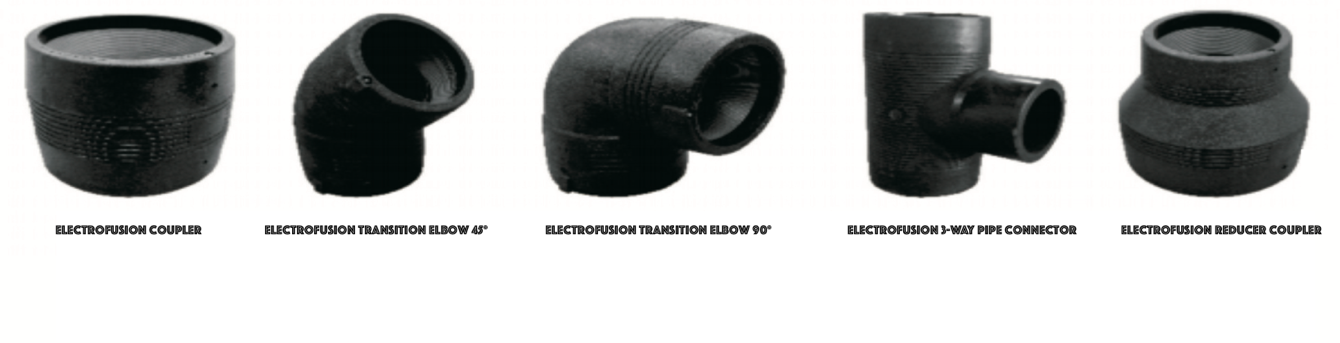

Product Performance Indicators

- Elongation at Break

Elongation at break is a key indicator of PE pipe flexibility, reflecting its adaptability to uneven ground settlement and seismic resistance. National standards require an elongation at break ≥350%, while high-quality PE pipes can exceed 700% in testing. - Longitudinal Reversion Rate

This measures dimensional stability under thermal influence, indicating deformation after heating. The standard requires ≤3% to ensure minimal size changes during installation and use. - Oxidation Induction Time (OIT)

OIT evaluates thermal stability and anti-aging performance, directly correlating with long-term heat resistance. It measures the time before autocatalytic oxidation begins under high temperatures, assessing material durability. - Pressure Resistance

A critical technical parameter, PE water pipes are classified into six pressure grades per GB/T 13663-2000: 0.4 MPa, 0.6 MPa, 0.8 MPa, 1.0 MPa, 1.25 MPa, 1.6 MPa (PE100 pipes, max. 16 kg/cm²).

Pressure tests are conducted at 5× working pressurefor 24 hours to ensure reliability. - Temperature Derating Factor

For PE piping systems operating continuously above 20°C, the Maximum Operating Pressure (MOP) is adjusted using a temperature derating coefficient to maintain pressure resistance in high-temperature environments. - Physical Performance Metrics

The physical performance indicators of PE water supply pipes also include hydrostatic strength at various temperatures, elongation at break, longitudinal reversion rate, etc. For example, the hydrostatic strength of PE water supply pipes at 20°C (i.e., hoop stress of 9.0 MPa) must ensure no cracking or leakage after 100 hours; at 80°C (hoop stress of 4.6 MPa), the pipes must withstand 165 hours under these conditions.

Product Specifications

Pipe Connectors

The main connection methods for pipes are:

- ① For DN≤63, use socket fusion (heat fusion) or electrofusion connections;

② For DN≥75, butt fusion (heat fusion) or electrofusion connectionsare preferred;

③ For connections to metal pipes and pipe accessories, flange connections or transition fittingscan be used.

- Socket Fusion Connection

When using this method, a socket fusion welding machine is employed. The specific steps are as follows:

① Check the pipe surface quality. The connection area should be clean, free of cracks, smooth, flat, and without burrs.

② Measure the socket depth and mark the insertion line clearly on the pipe surface.

③ Use a special scraper to treat the pipe’s connection surface, ensuring a fresh layer all around. Bevel the pipe end if needed; the bevel angle should be 30°, and the bevel length should not exceed 2.0 mm.

④ Wipe the socket surface of the fitting with a dry cloth to ensure it is clean and free of debris.

⑤ Insert the pipe and fitting—without rotating—into the heating tool at the same time and heat the joint area.

⑥ Once the heating time is reached, quickly and evenly remove the pipe and fitting from the heater and push the pipe into the socket in one smooth motion, forming a raised bead around the joint.

⑦ Allow the pipe and fitting to cool completely for the specified time before performing the next operation.

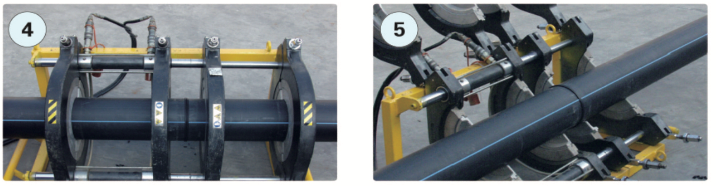

3. Butt Fusion

When using this connection method, a butt fusion welding machine shall be employed. The specific procedures are as follows:

① Prepare all required tools.

② Secure the pipes in the welding machine fixtures, clean and mill the connection ends, align the pipes, ensuring offset does not exceed 10% of wall thickness.

③ Insert the heating plate.

④ After heating, remove the heating plate, promptly join the heated surfaces, increase to fusion pressure and maintain pressure during cooling.

⑤ Fusion completed

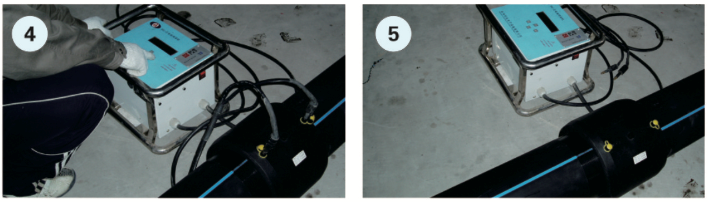

4. Electrofusion Connection

Electrofusion socket connection features convenient and rapid joining, minimal external interference, and offers economic advantages for small-diameter pipelines (DN≤63) or in challenging construction scenarios. Connection schematic is shown below:

① Clean contaminants from the pipe connection surface and mark the insertion depth.

② Remove the surface oxide layer.

③ Slide the electrofusion fitting onto the pipe, ensuring proper alignment on the same axis.

④ During electrified heating, a small amount of molten material should visibly push out from the inspection port.

⑤ Allow the joint to cool naturally to complete the electrofusion process.

Precautions: During connection, the selected voltage and heating time for electrified heating must comply with the specifications of the electrofusion equipment manufacturer. During the cooling period of electrofusion, do not move the connected parts or apply any external force to them.

5. Transition Connection

For connections between pipes and metal pipes/pipeline accessories (such as valves, water meters, etc.), threaded or flanged transition fittings shall be used at the joint interfaces.

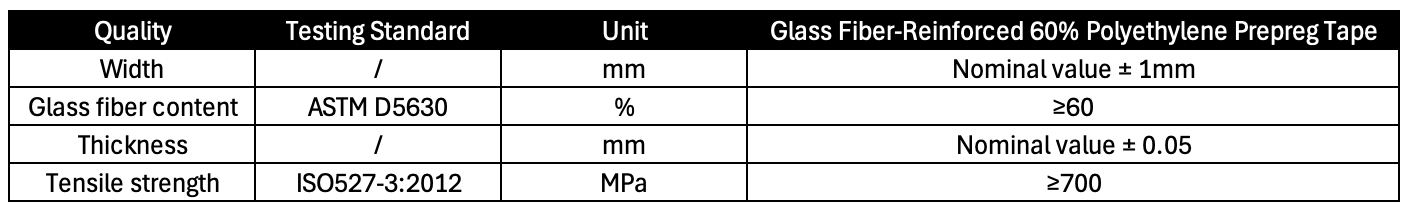

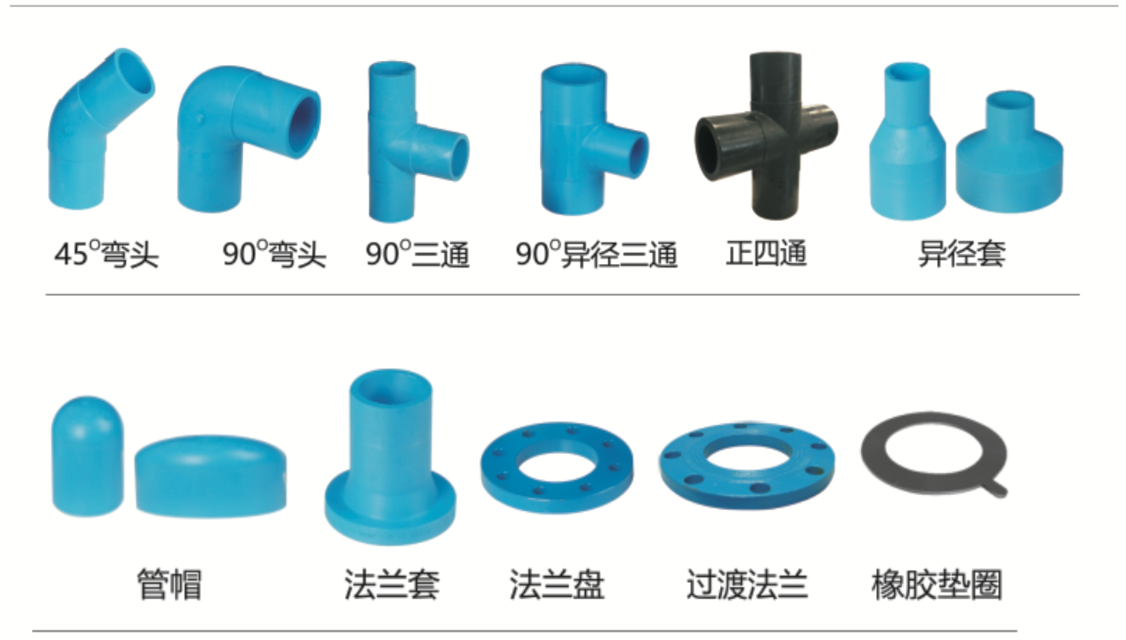

Pipe Fittings Series

Injection-Molded Socket Fittings: Injection-molded fittings are blue or black in color for sizes DN20 to DN90. For DN110 and above, they are also available in blue or black. Color options: Blue, Black.

Injection-Molded Butt Fittings: Injection-molded fittings are blue or black for sizes DN20 to DN90. For DN110 and above, they are also blue or black. Color options: Blue, Black.

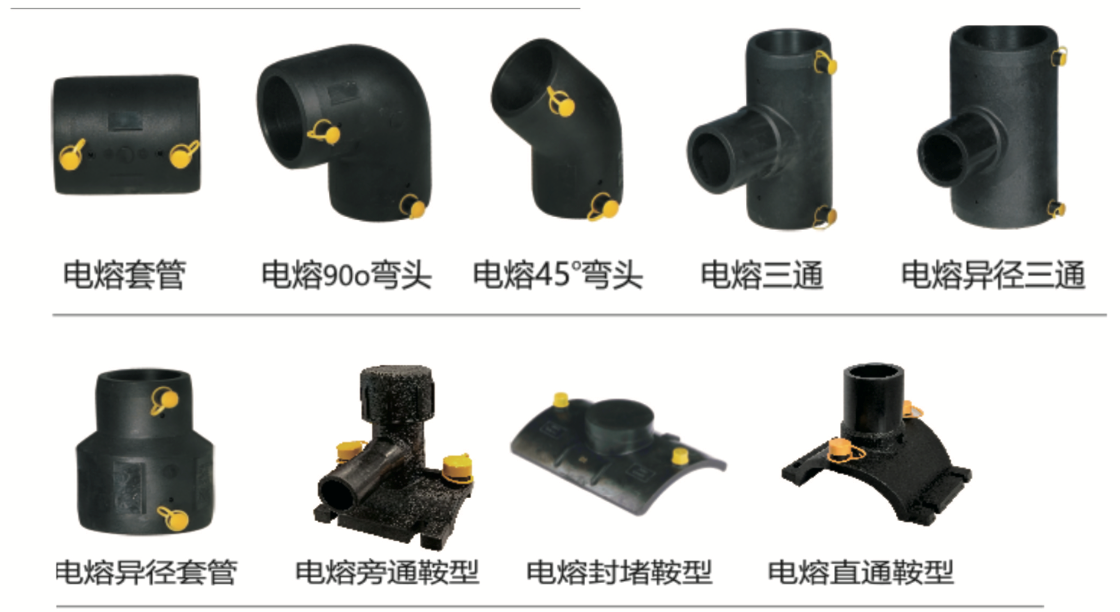

Electrofusion Fittings: Electrofusion fittings are black in color.

Continuous Steel Ribbed Polyethylene Pipe (SRPP)

Product Introduction

The composite pipe has been widely used in many fields. Continuous Steel Ribbed Polyethylene Pipe (SRPP) has specific advantages of corrosion resistance, anti-settling, long service life, convenient transportation and construction installation with lower costs.

By Comparing with traditional steel wired reinforced composite pipe, this brand-new composite pipe machinery technology supported by US national standards, with nearly 30 to 40 years of experience in the United States. Under Analysis and verification of the quality & service life for this kind of pipe. the pipe service life can be reached 80 years.

Product Features

Lower Manufacturing Cost

The composite pipe machinery can be pulled to the site for production if meet required environment condition, which reducing the pipe transportation cost. There is no need to change the mold to manufacture any diameters between 600mm – 3000mm. Compared with the double wall bellows, steel wired reinforced pipes and Carat pipes, the production efficiencies are well considered since there’s no need to temporally pause the machine in order to change the mold.

Lower Composite Pipe Machinery Cost

SRPP has convenient production procedure, one equipment can produce 600mm+ pipe caliber. If modified to one equipment with three sets of devices that can produce any specification pipes between 600mm – 3000mm caliber.

Lower Transportation Cost

All equipment can be assembled in a flatbed truck, which means SRPP can be produced on the truck. It saves a lot of costs for large-caliber pipe transportation.

More Reliable

Steel Ribbed PE pipes are perfectly combining mechanical and chemical system to ensure composite integrity by using high tightness of the cover layer,better weathering and impact resistance, strong corrosion-resistance polymeric membranes to ensure safety and be ready for long-term operation.

Product Applications

SRPP is suitable for drainage pipes (low-pressure drainage, gravity drainage), highway culverts, animal crossings, wind turbine foundation sleeves, and low-pressure water supply pipes.

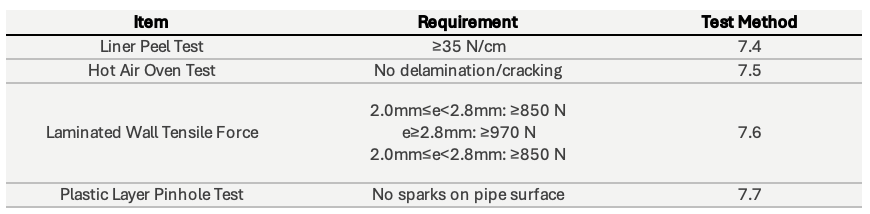

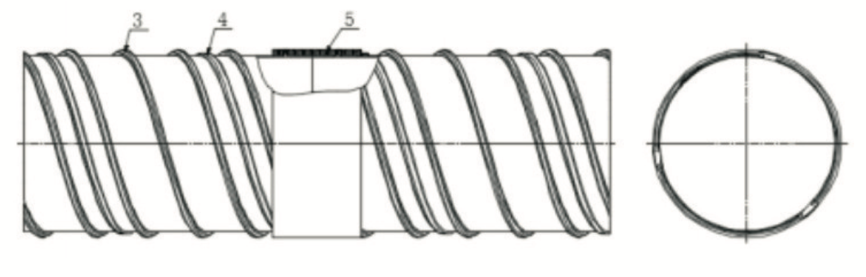

Product Specifications

Product Specifications

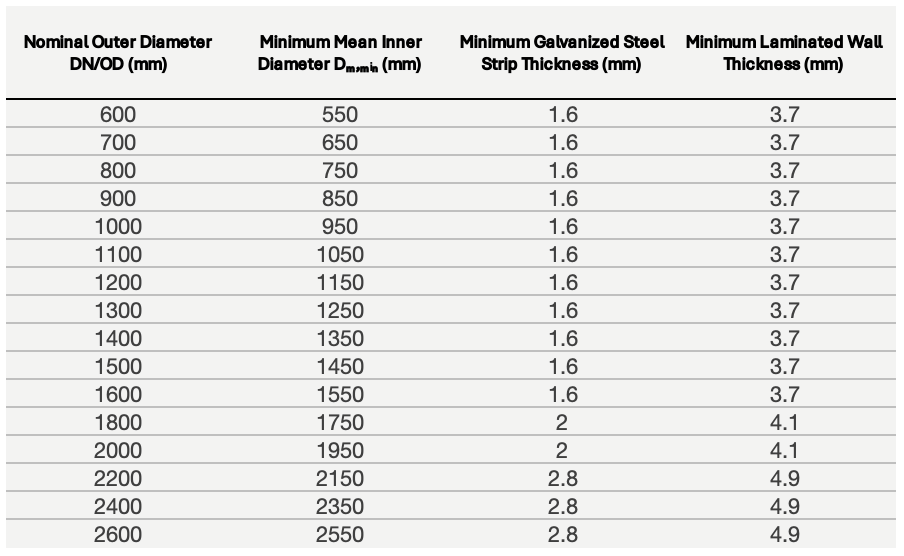

Pipe Connection

Common connection methods include heat-shrink connection and electrofusion connection.

Other methods can be determined through mutual agreement between the supplier and the buyer.

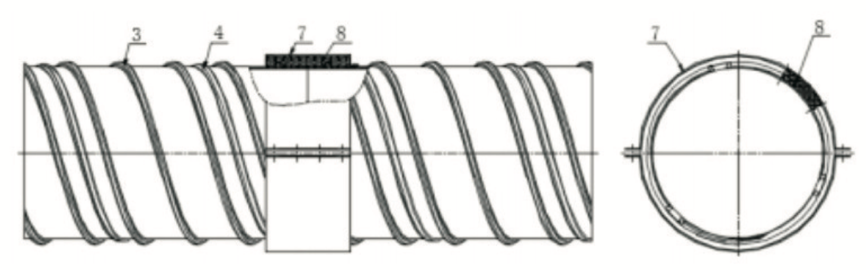

Heat-Shrink Connection

- Steel reinforcement

- Steel crimp

- Heat shrink tape

Clamp Connection

- Steel reinforcement

- Steel crimping joint

- Clamp

- Neopreme foam rubber board

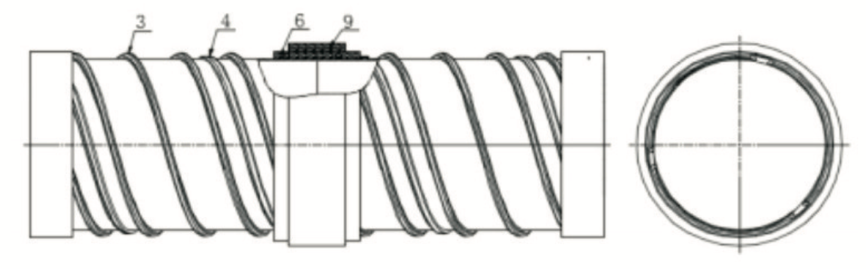

Electrofusion Connection

- Steel reinforcement

- Steel crimping joint

- Socket

- Electrical heating tape