Penetrating-Consolidant Repair Material

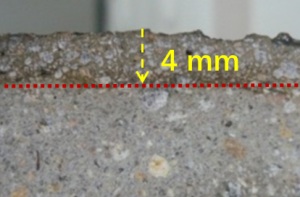

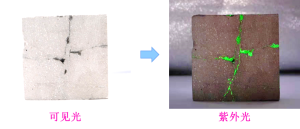

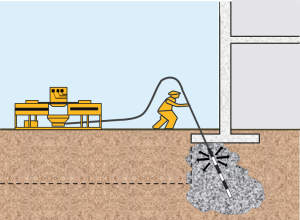

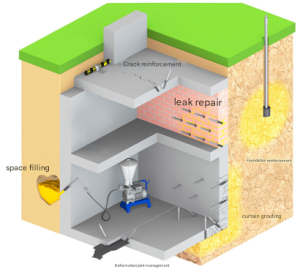

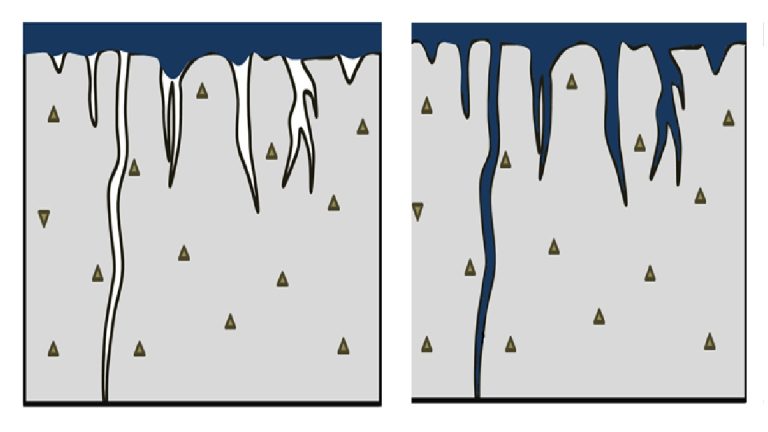

This material has excellent penetration properties and can penetrate into the cracks and pores of concrete and solidify and cross-link in situ, firmly bonding damaged and failed concrete together to form a three-dimensional spatial solidification body equivalent to an interpenetrating network structure, thereby achieving rapid repair and reinforcement of concrete. In particular, this material can directly consolidate fine sand, soft mud, gravel, etc. into rock (compressive strength >100 MPa). When this material is used for surface protection, it not only forms a coating on the surface of the concrete, but also forms a “rooted” consolidation reinforcement layer deep into the structural layer, thus eliminating capillaries, pores and micro-cracks formed by the porous media of the concrete, making the anti-corrosion layer on the surface of the concrete as thick as millimeters, increasing the surface strength of the concrete by more than twice, and having excellent corrosion resistance and anti-penetration properties.

At present, this technology has been widely used in the reinforcement, waterproofing, anti-seepage, and anti-corrosion of subways, tunnels, bridges, seaports and terminals, hydropower dams, and civil buildings, and has achieved good results. This achievement can effectively improve the mechanical properties, impermeability and durability of concrete, and has important application value in national large-scale projects, industrial construction, civil construction and other fields.

Material Key Technical Indicators:

- Initial viscosity <30 mPa.s;

- Operation time: 1-24 h;

- Compressive strength >100 MPa, close to the strength of ultra-high performance concrete;

- Bonding strength: Thousand bonding>4.0MPa, wet bonding>3.5MPa, both are concrete damage;

- Corrosion-resistant medium: No cracking, peeling or peeling after immersion in 10wt% H2SO4 (acid), 10wt% NaOH (alkali), 10wt% NaCl (salt) for 90 days.