Stainless Steel Longitudinally Welded Gas Pipe

Product Introduction:

Stainless Steel Longitudinally Welded Gas Pipe is fabricated using high-quality stainless steel plates or coils, this pipe is formed through rolling and shaping with precision machinery and dies, then welded along the longitudinal seam. It offers high precision, uniform wall thickness, and a smooth, polished surface on both the interior and exterior. The pipe is safe, reliable, and ideally suited for positive pressure ventilation, negative pressure ventilation, and gas extraction in coal mines.

Product Features:

- Safety: Flame-retardant and anti-static properties, fully compliant with underground safety standards.

- Lightweight: Low unit weight per meter, making it easy to install in underground applications.

- Corrosion Resistance: Suitable for operation in acidic and alkaline corrosive environments, offering long service life.

- Low Flow Resistance: Smooth inner pipe wall ensures minimal flow resistance and low wind noise.

- High Quality: Thin-walled and lightweight while meeting rigidity and negative pressure requirements.

- Easy Connection: Can be connected using flanges for fast and secure installation.

Product Applications:

Featuring lightweight construction, excellent corrosion resistance, high safety, low flow resistance, and easy connection, this pipe is widely used in positive pressure ventilation, negative pressure ventilation, and gas extraction across various industries such as power, metallurgy, mining, coal, and chemical processing.

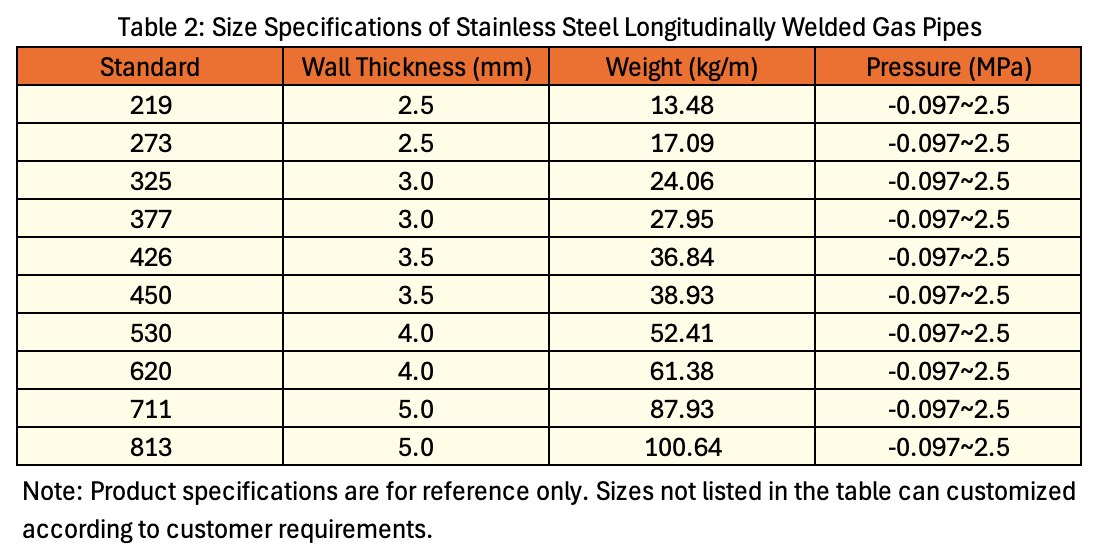

Product Advantages:

Compared to carbon steel pipes of the same specifications and pressure rating, stainless steel longitudinally welded gas pipes are approximately 1/2 to 1/3 lighter in weight. The advantage becomes even more significant as pressure and diameter increase.

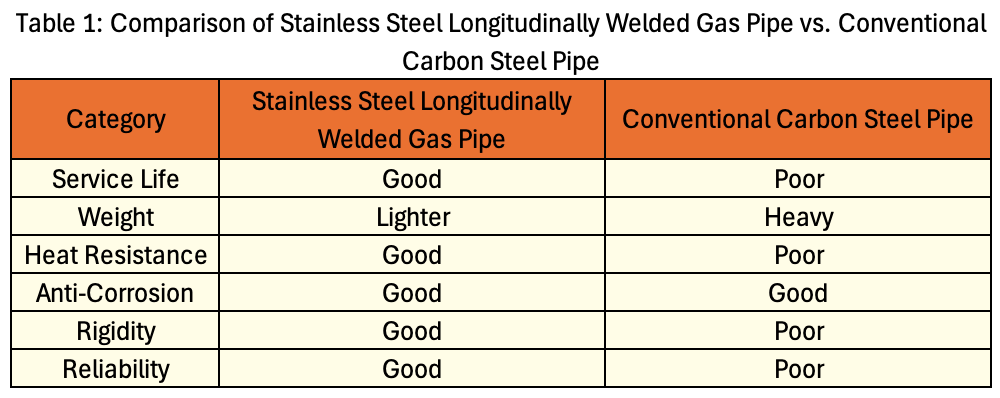

Product Specifications: