Continuous Steel Ribbed Polyethylene Pipe (SRPP)

Product Introduction:

The composite pipe has been widely used in many fields. Continuous Steel Ribbed Polyethylene Pipe (SRPP) has specific advantages of corrosion resistance, anti-settling, long service life, convenient transportation and construction installation with lower costs.

By comparing with traditional steel wired reinforced composite pipe, this brand-new composite pipe machinery technology supported by US national standards, with nearly 30 to 40 years of experience in the United States. Under Analysis and verification of the quality & service life for this kind of pipe. the pipe service life can be reached 80 years.

Product Features:

- Lower Manufacturing Cost: The composite pipe machinery can be pulled to the site for production if meet required environment condition, which reducing the pipe transportation cost. There is no need to change the mold to manufacture any diameters between 600mm – 3000mm. Compared with the double wall bellows, steel wired reinforced pipes and Carat pipes, the production efficiencies are well considered since there’s no need to temporally pause the machine in order to change the mold.

- Lower Composite Pipe Machinery Cost: SRPP has convenient production procedure, one equipment can produce 600mm+ pipe caliber. If modified to one equipment with three sets of devices that can produce any specification pipes between 600mm – 3000mm caliber.

- Lower Transportation Cost: All equipment can be assembled in a flatbed truck, which means SRPP can be produced on the truck. It saves a lot of costs for large-caliber pipe transportation.

- More Reliable: Steel Ribbed PE pipes are perfectly combining mechanical and chemical system to ensure composite integrity by using high tightness of the cover layer,better weathering and impact resistance, strong corrosion-resistance polymeric membranes to ensure safety and be ready for long-term operation.

Product Applications:

SRPP is suitable for drainage pipes (low-pressure drainage, gravity drainage), highway culverts, animal crossings, wind turbine foundation sleeves, and low-pressure water supply pipes.

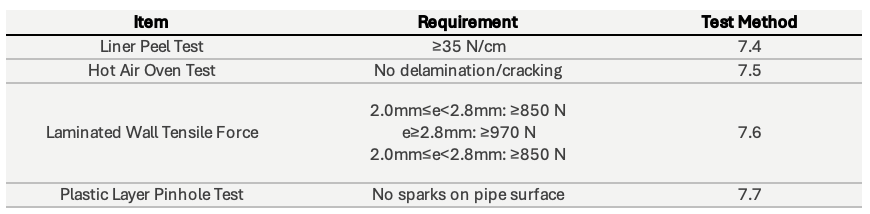

Physical Performance Requirements for Pipes:

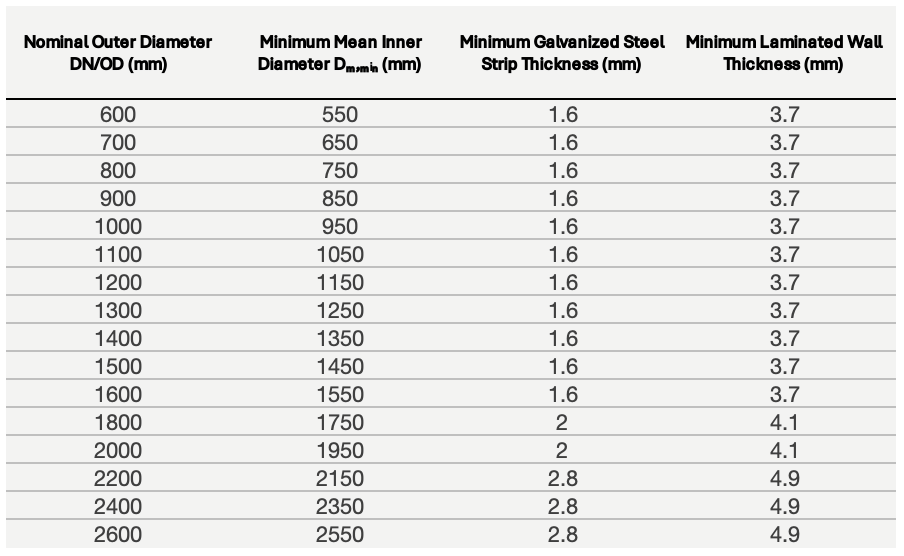

Product Specifications:

Pipe Connection:

Common connection methods include heat-shrink connection and electrofusion connection.

Other methods can be determined through mutual agreement between the supplier and the buyer.

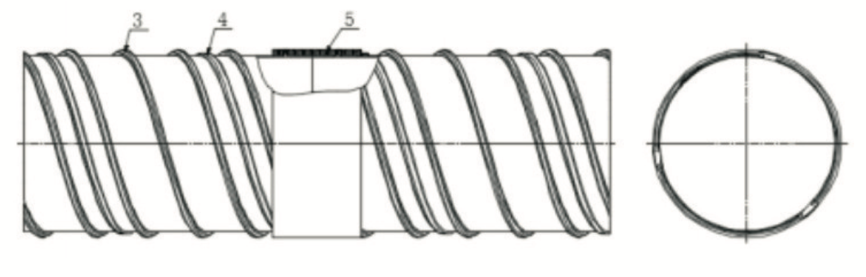

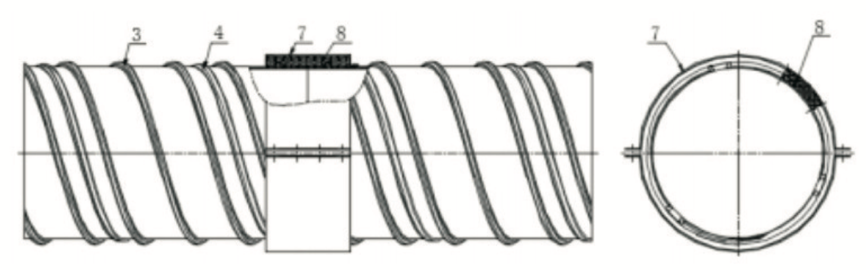

Heat-Shrink Connection

- Steel reinforcement

- Steel crimp

- Heat shrink tape

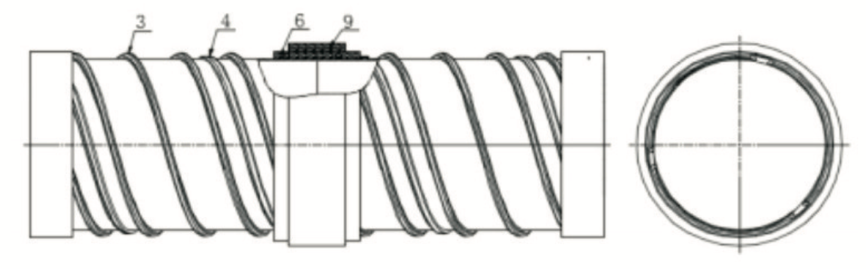

Clamp Connection

- Steel reinforcement

- Steel crimping joint

- Clamp

- Neopreme foam rubber board

Electrofusion Connection

- Steel reinforcement

- Steel crimping joint

- Socket

- Electrical heating tape